ProCAM – Innovative motor technology for the climate and the environment!

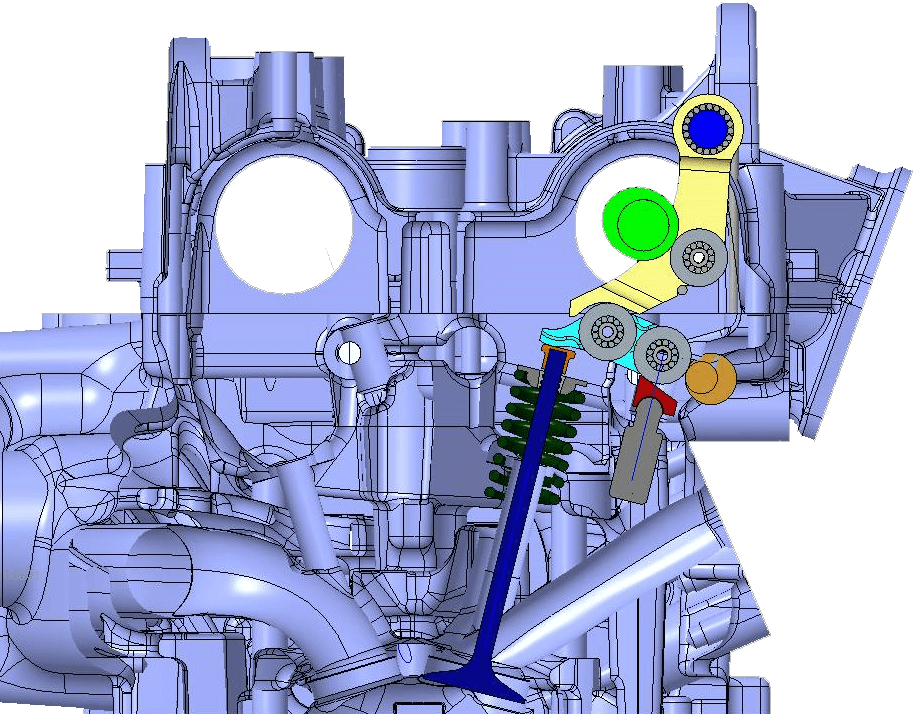

The ProCAM system is a fully variable mechanical valve lift system. The system is easy to implement in existing series engines and is characterized by minimal frictional forces, fast response and compact design.

Technical features

Thanks to the extremely compact installation space, the ProCam system can be easily integrated into an existing cylinder head design.

Functionality

An intermediate lever with a cam geometry is installed between the camshaft and the roller finger follower. The roller finger follower is mounted on a sliding block and can be adjusted via an eccentric shaft. If the roller finger follower is now adjusted on the link, the valve lift changes between zero lift and maximum lift. This eliminates the need for a throttle valve, the engine operates more efficiently and emissions are significantly reduced.

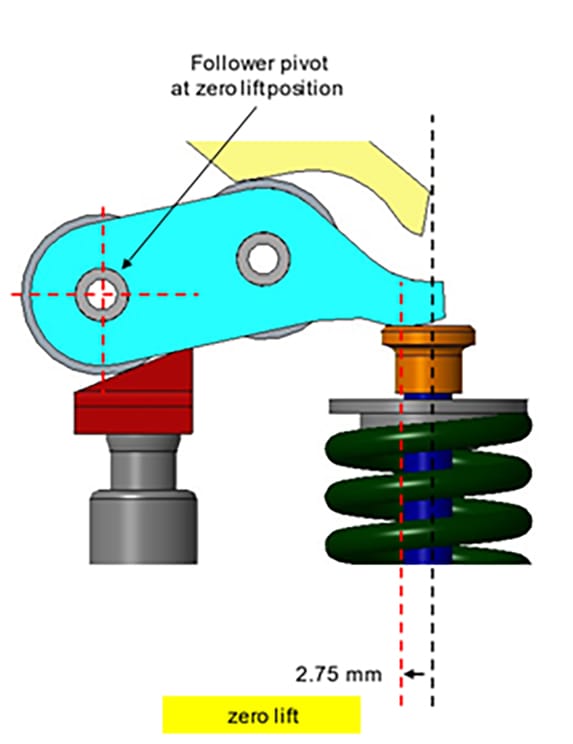

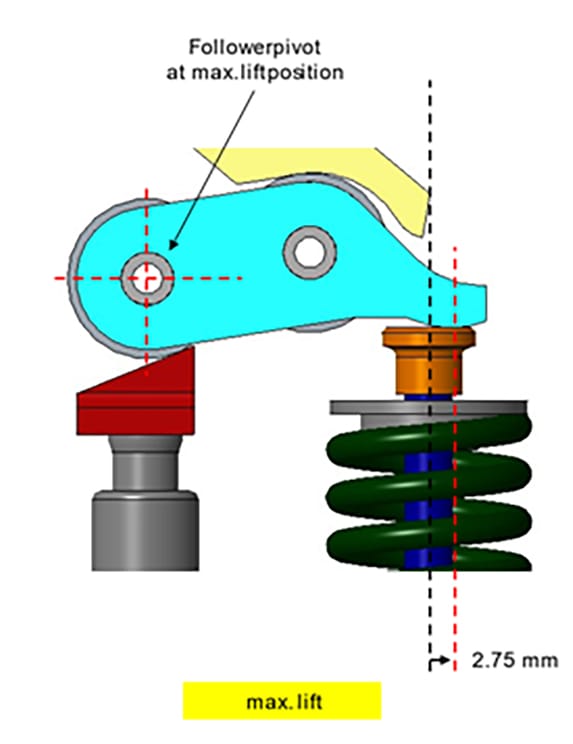

Min and Max Stroke

In the zero lift position, the splitter is set so that no valve lift is possible, even at maximum camshaft lift. This is prevented by the cam geometry of the intermediate lever in conjunction with the splitter.

Zero lift with minimum camshaft lift

Zero lift with maximum camshaft lift

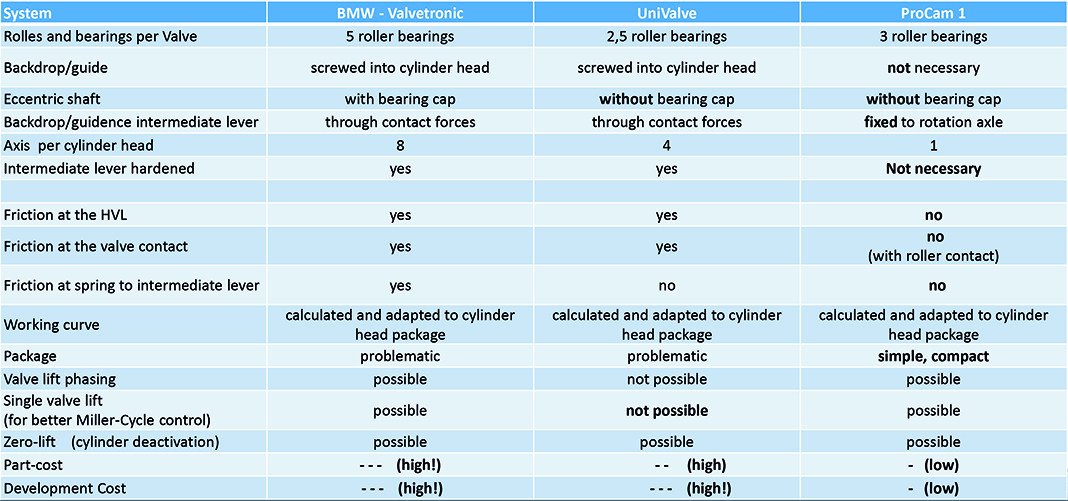

System comparison

Advantages of the ProCam system compared with the Valvetronic system and the UniValve system.

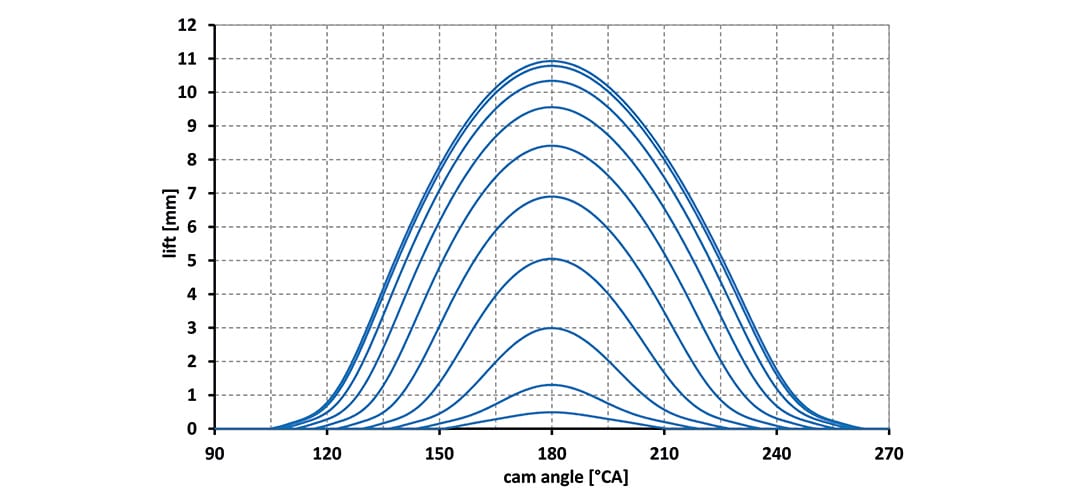

Valve lift curve

ProCam valve lift curve lift over crank angle.

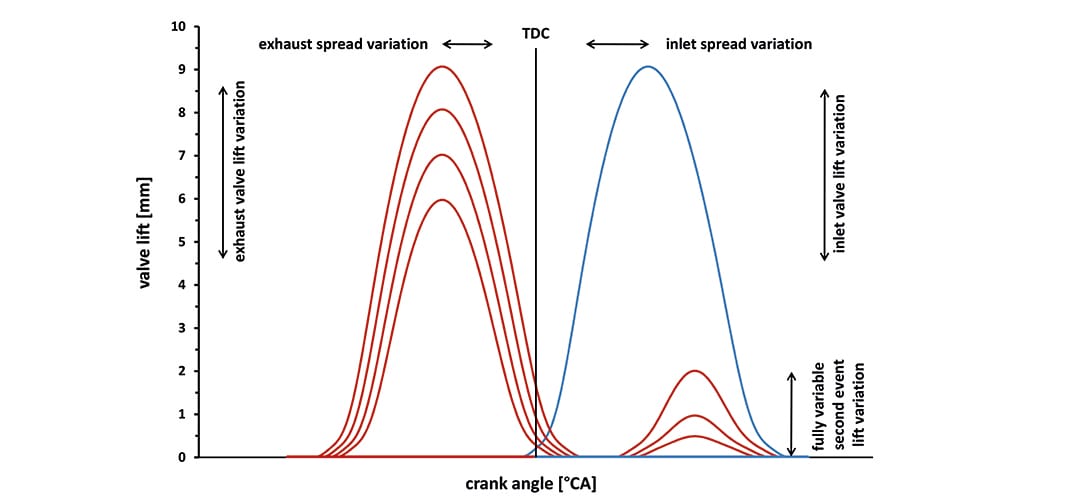

Second Event

Setting options for different variations of the intake spread and exhaust gas spread

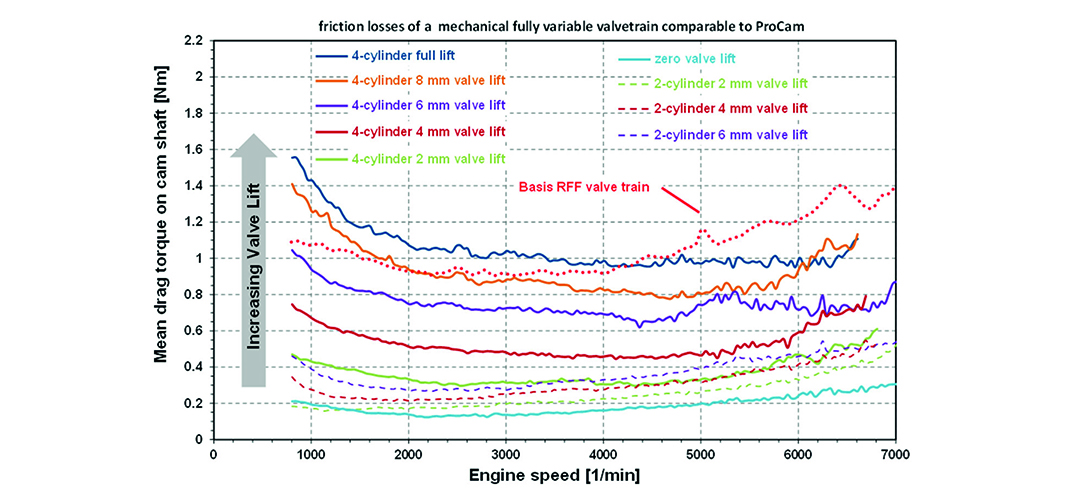

Friction

ProCam minimizes internal friction losses through the use of roller contacts and needle bearings.

ProCam Features

- Valve stroke adjustment range from 0 to 11 mm

- Max adjustment in less than 200 ms

- 70 to 300 °KW adjustment range of the control times

- Can be used up to over 7000 rpm

- 10 % less fuel consumption by minimizing pump losses at n=2000 rpm; BMEP = 2 bar

- Torque increase at low engine speeds

- Low friction due to roller contacts

- less than 0.2 mm stroke deviation with small strokes

- less than 0.1 mm stroke deviation at idling speed

- Possibly small deviation of the camshaft position

- Cost-effective and simple mechanical production

- Possibility of a second event for a single valve

- Possibility of incremental strokes